Product Description

Key features:

- Suitable for use with or without an input isolation transformer

- Direct-to-line connection (transformerless) provides lowest cost of ownership

- Simple drive system integration

- Three in – three out cabling technique for quick and easy installation

- Suitable for new or existing induction motors

- Modular design provides high reliability and low maintenance costs

ABB provides low harmonic and regenerative versions of the

ACS 2000.

ACS 2000, low harmonic drives

ABB’s low harmonic drives offer optimal low harmonic performance which does not require any additional filtering. Line side harmonics of the ACS 2000 are compliant with all relevant standards. This avoids the need for harmonic analysis or the installation of a multi-pulse transformer, network filters or other additional equipment for harmonics reduction.

ACS 2000, regenerative drives

ACS 2000 regenerative drives provide enhanced active braking and power factor correction.

The AFE enables regenerative braking which allows full power flow both in motoring and generating mode. Regeneration offers significant energy savings compared to other braking methods as energy is fed back to the supply network. Regeneration is especially suitable for applications with frequent starts and stops. It allows energy efficient continuous braking of applications such as downhill conveyors or expanders in gas pipelines.

The AFE can also provide reactive power (VAR) compensation. With VAR compensation, the voltage level can be controlled to stay within tight limits. A smooth network voltage profile can be maintained and reactive power penalties can be avoided.

| Type of converter | ||

| VSI Voltage Source Inverter |

||

| Typical applications | ||

| Pumps, fans, conveyors, extruders, mixers, compressors, grinding mills, suitable for retrofit of existing motors | ||

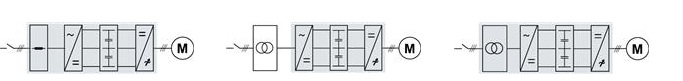

| Typical system diagrams | ||

ACS 2000 diagram |

||

| Converter cooling | ||

| Air (A) | ||

| Power range | ||

| A: 250 – 2,500 kW | ||

| Input section | ||

| Active Front End (AFE): high-voltage IGBTs Diode Front End (DFE): 24-pulse rectifier |

||

| Output section | ||

| High-voltage IGBTs: 5-level VSI, 9-level output waveform | ||

| Output voltage | ||

| 4.0 – 6.9 kV | ||

| Max. output frequency | ||

| 75 Hz | ||

| Field weakening | ||

| >25 Hz (max. 1:3) | ||

| Special features & benefits | ||

| – Constant network power factor over whole speed range – DTC (Direct Torque Control) – Fuseless |

||

| Examples of options | ||

| – Available for direct-to-line connection, for connection to a separate two-winding transformer or with an integrated transformer – Reactive power compensation and regeneration – Configurable disconnect package – Output sine filter – Redundant cooling fan – Extended I/Os for supervision functions – Various fieldbus interfaces |

||

| Type of motor | ||

| Induction motor | ||

Công Ty TNHH Thiết Bị Công Nghiệp Sao Việt chuyên cung cấp máy móc, thiết bị, phụ tùng các loại máy, kết hợp với các dịch vụ lắp đặt sửa chữa, bảo trì các loại máy móc, thiết bị công nghiệp.

Công Ty TNHH Thiết Bị Công Nghiệp Sao Việt chuyên cung cấp máy móc, thiết bị, phụ tùng các loại máy, kết hợp với các dịch vụ lắp đặt sửa chữa, bảo trì các loại máy móc, thiết bị công nghiệp.