Product Description

Features & benefits:

- For standard induction, synchronous and permanent magnet motors

- Air cooling

- Available with integrated or separate input transformer

- Monitoring tool for remote real-time access to the drive available

- Fast and accurate control performance due to DTC

- High reliability due to low parts count

- High system efficiency due to VSI-MF topology, IGCTs and DTC

- Small footprint due to high power density

- Optimal network friendliness due to 36-pulse configuration

Medium voltage drive for control of motors up to 6.9 kV

ACS 5000 |

|

| Type of converter | |

| VSI Voltage Source Inverter |

|

| Typical applications | |

| Compressors, extruders, pumps, fans, grinding mills, conveyors, blast furnace blowers, gas turbine starters | |

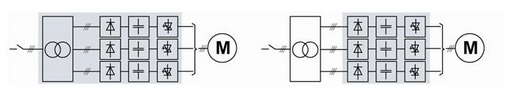

| Typical system diagram | |

ACS 5000 diagram |

|

| Converter cooling | |

| Air (A) / Water (W) | |

| Power range | |

| A: 2 – 7 MW W: 7 – 36 MW (higher on request) |

|

| Input section | |

| Diodes: 36-pulse rectifier | |

| Output section | |

| IGCTs: 5-level VSI, 9-level output waveform | |

| Output voltage | |

| 6.0 – 6.9 kV (optional 4.16 kV) | |

| Max. output frequency | |

| 75 Hz (optional 250 Hz) | |

| Field weakening | |

| >35 Hz (max. 1:2, higher optional) | |

| Special features & benefits | |

| – Constant network power factor over whole speed range – DTC (Direct Torque Control) – Fuseless |

|

| Examples of options | |

| – Synchronous bypass – Extended I/Os for supervision functions – Integrated input transformer |

|

| Type of motor | |

| Induction, synchronous or permanent magnet motor | |

Công Ty TNHH Thiết Bị Công Nghiệp Sao Việt chuyên cung cấp máy móc, thiết bị, phụ tùng các loại máy, kết hợp với các dịch vụ lắp đặt sửa chữa, bảo trì các loại máy móc, thiết bị công nghiệp.

Công Ty TNHH Thiết Bị Công Nghiệp Sao Việt chuyên cung cấp máy móc, thiết bị, phụ tùng các loại máy, kết hợp với các dịch vụ lắp đặt sửa chữa, bảo trì các loại máy móc, thiết bị công nghiệp.